Mount G&D operates with cutting-edge equipment to produce elevator components that feature precision sheet metal processing and exceptional durability.

Precise Bending & Consistent Quality

Accurate bending and forming of sheet metal components

Processing of various components such as elevator control panel enclosures and structural reinforcements

High-Precision Bending Process Precision shaping with a tolerance range within ±0.1mm

High-Durability Equipment Capable of processing thick metal sheets, ensuring robust durability

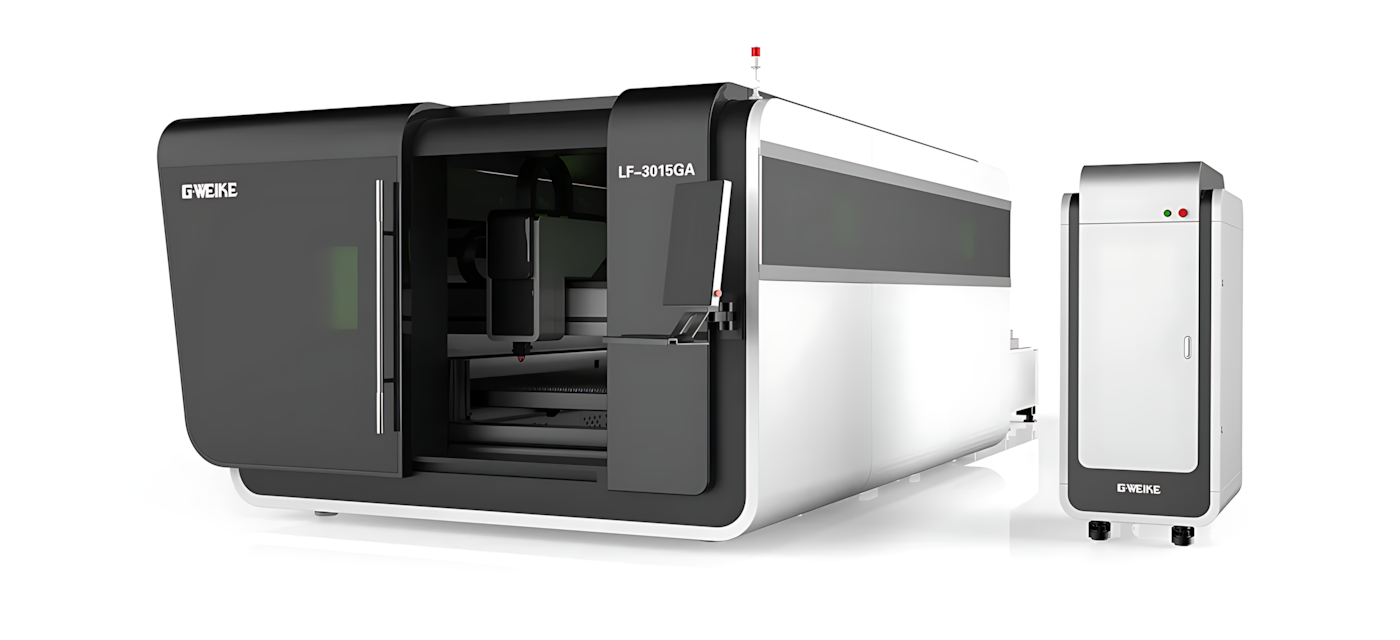

Precision Cutting & High-Speed Processing

Precision cutting and complex shape processing of metal sheets

Maintains consistent quality and enhances production speed

Ultra-Precision Processing Equipped with a high-power laser offering ±0.05mm precision

High-Speed Processing Utilizes an automated system to reduce production time and optimize processing speed

Non-Contact Cutting Method Non-contact processing prevents micro-damage and enhances finish quality

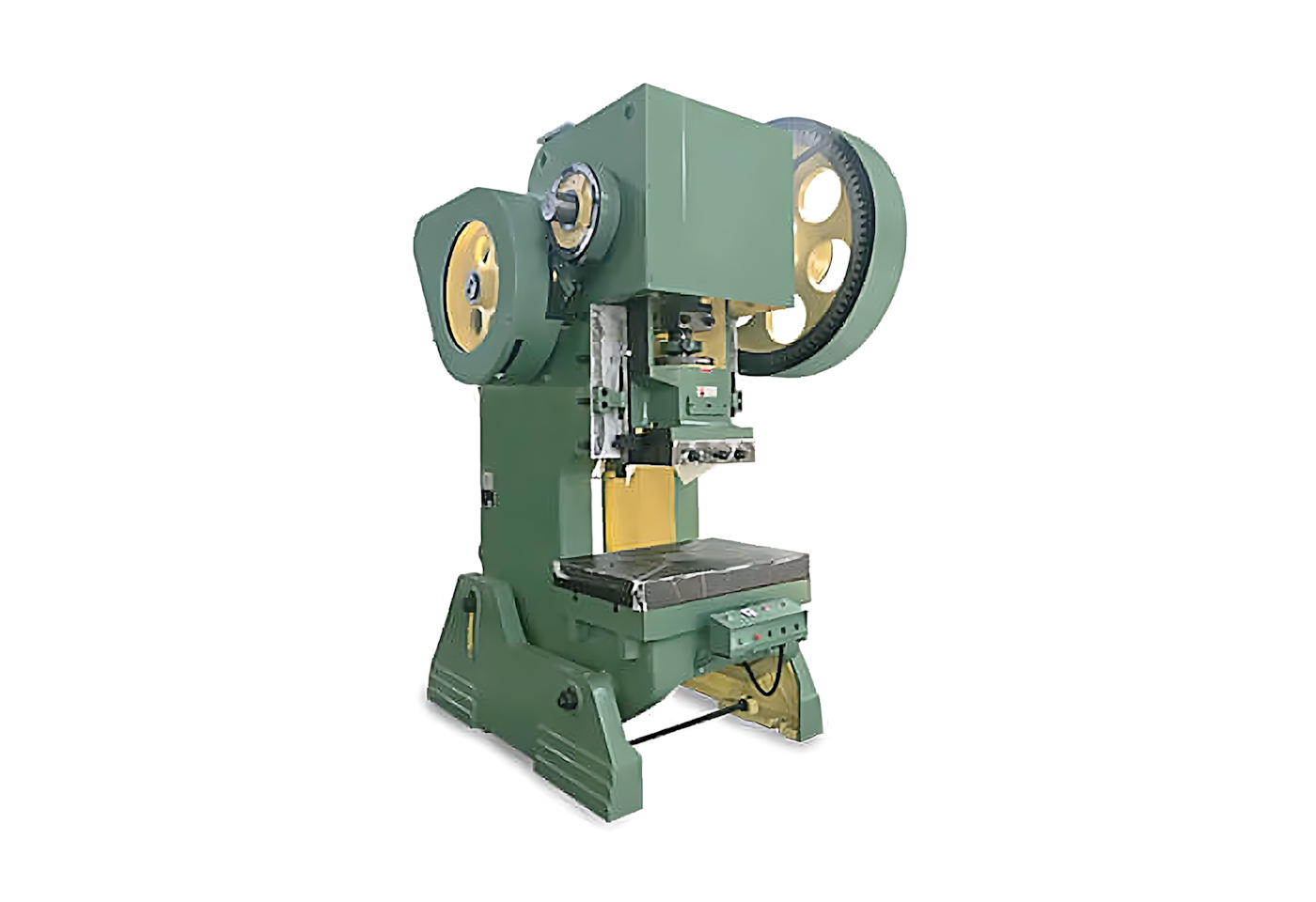

High-Precision Punching & High-Speed Processing

Precise punching and complex processing of metal sheets

Performs multi-stage punching operations for complex shapes

Maintaining consistent quality and enabling mass production of elevator components

Automated Precision Control System High-precision machining using Computer Numerical Control (CNC) technology

High-Speed Punching Process Production of parts requiring high-volume machining in a short period of time

Multi-Stage Processing Capability Simultaneous processing of various metal machining methods (punching, forming, cutting)

Precision Punching & Optimized for Mass Production

High-precision punching and forming of metal sheets

Maintaining consistent quality and mass production of elevator components

High-Speed & High-Strength Punching Process Efficient processing of high-strength metal materials

Consistent Quality Maintenance Mass production of parts with consistent specifications

Automated Production Process Precision machining based on CNC (Computer Numerical Control) technology

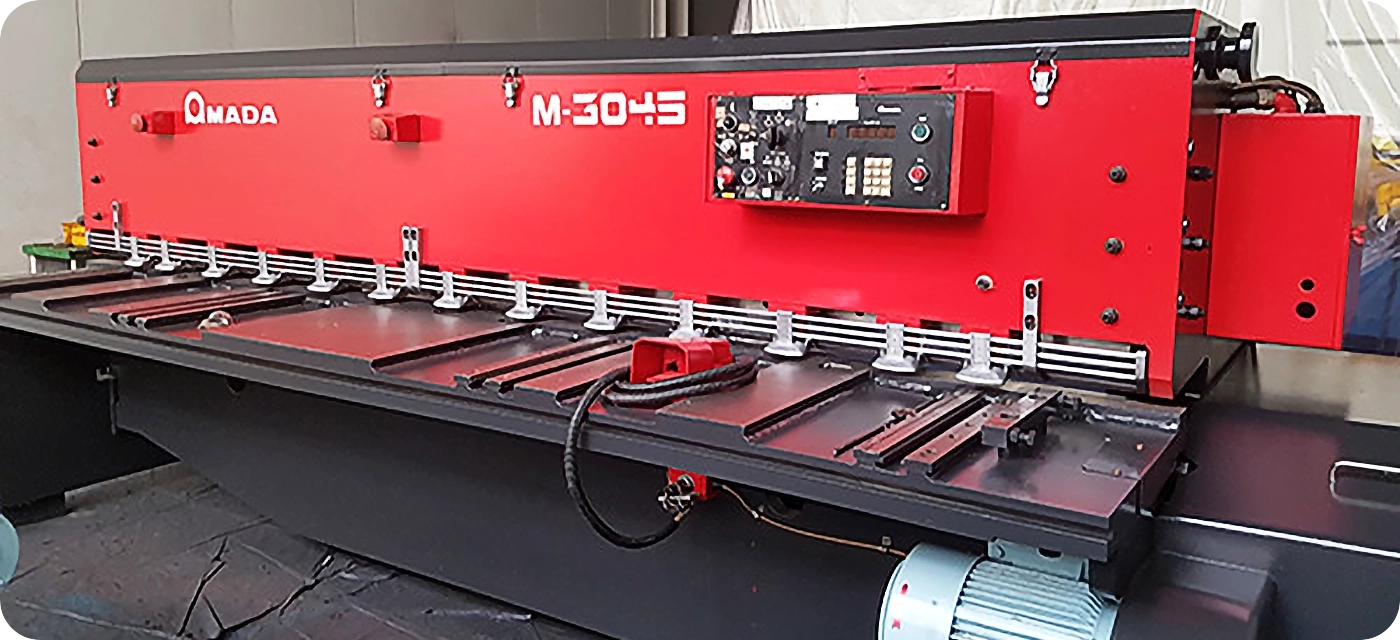

Precision Cutting & Consistent Quality

Precision cutting and size adjustment of metal sheets

Maintaining consistent quality and optimizing post-processing (bending and punching)

Accurate Dimension Control Precise cutting within a tolerance of ±0.1mm

High-Speed Processing System Completing high-volume sheet metal cutting in a short period of time

Optimized for Subsequent Processing Improving production efficiency through integration with bending and punching processes

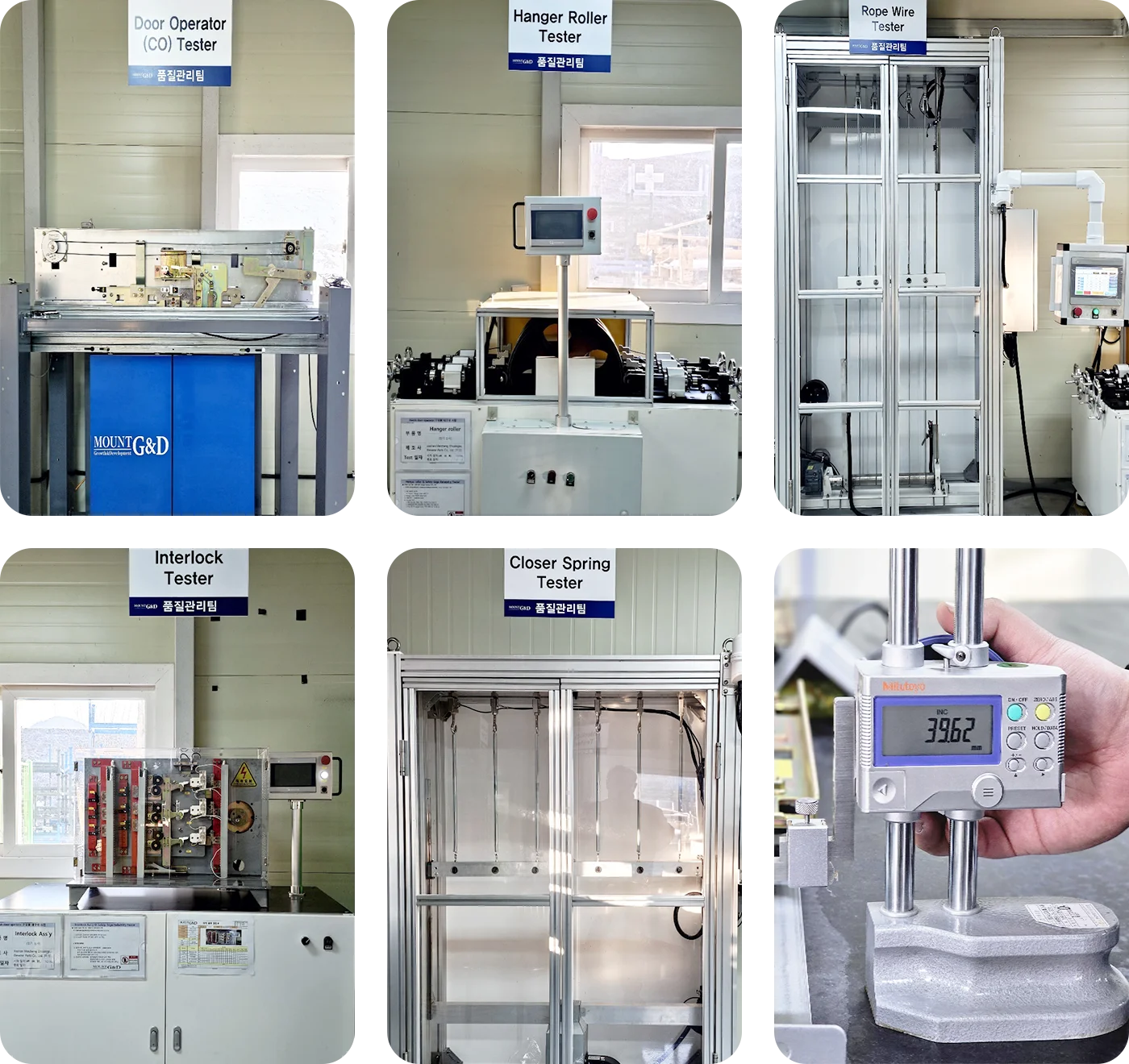

Precision Assembly & Reliability Testing

Precision assembly and performance testing of the Elevator Door Operator (HDO)

Verification of the durability and operational status of each component

Automated Precision Assembly Maintaining consistent quality through automated assembly processes

Real-World Simulation Testing Conducting operation tests under conditions similar to those in an elevator environment

High-Durability Verification Ensuring long-term durability through repetitive testing